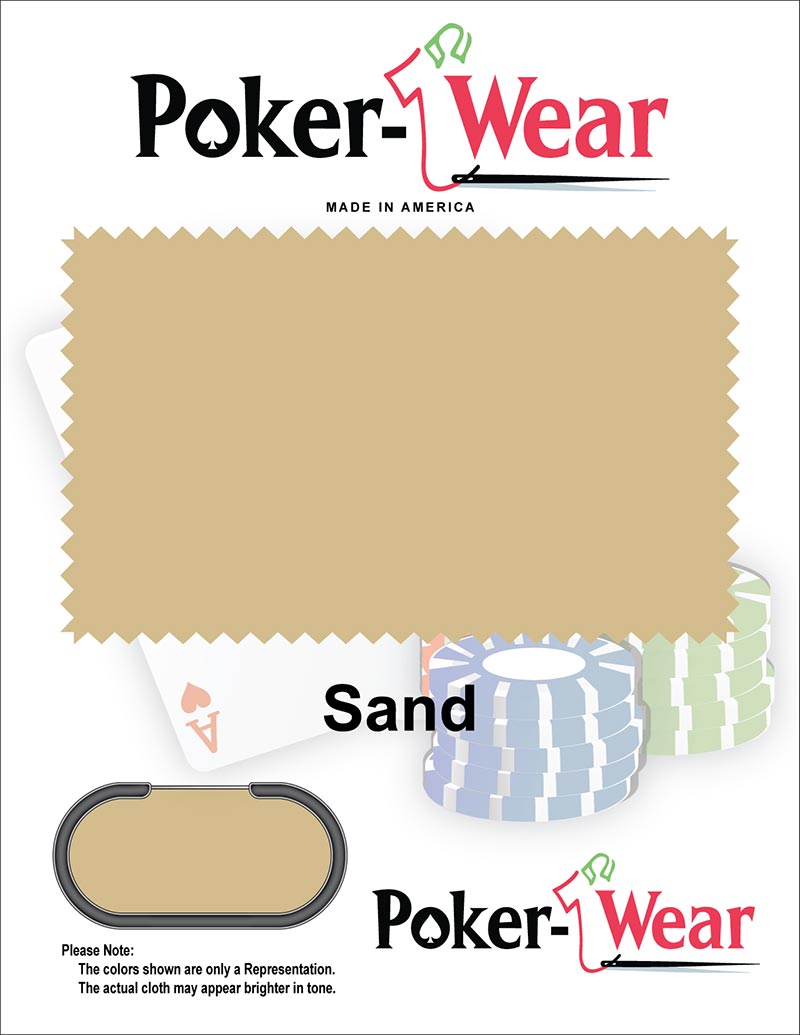

Sand Poker Table Felt

( $110 – $305 )

- Industry Standard for Durability, Speed, and Vibrant Colors

- Water Resistant

- Wide Array of Printable Colors

- Dye-Sublimated

Description

SAND POKER TABLE FELT

Poker-Wear gaming felts are the industry standard for durability, speed, and vibrant colors. Our sand poker table felt offers water resistance as well as an exceptionally smooth playing surface. It’s one of the most durable and attractive poker table felt in the industry today. Our vibrant colors are dye-sublimated onto a synthetic digital gaming layout, and will provide you with the same high quality felts found in poker rooms around the world.

We use state of the art printers and the latest technology in dye sublimation to provide you with sharp and vibrant colors. The colors won’t easily fade, and will provide you with a surface that will be suitable for long term professional use. We literally have hundreds of color to choose from. We can print any Pantone color for your poker table felt.

Our sand poker table felt is a great option for table builders and anyone looking for a casino quality replacement speed cloth. The playing cards will glide across the table with the help our synthetic digital gaming layout.

Sizes are 4′ x 4′, 8′ x 50″, and 9′ x 50″. A few extra inches of non-printed felt are added to each side to allow for securing the felt to the backside of the table.

Please contact us with any questions. Please allow 2 weeks for delivery via FedEx ground.

What is Dye Sublimation?

We produce our sand poker table felt via a process called Dye Sublimation. Dye Sublimation is a fairly new technology that has taken the printing world by storm. With Dye Sublimation printing, we are able to create permanent high definition prints on polyester fabric. We are able to create vibrant and bright colors, gradients, photos, and watermark designs. The day of the basic green casino layout has come and gone.

The Dye Sublimation process creates graphics by using inks in their gas form. The graphics are first printed on transfer paper, then with the use of a heat press, the transfer paper is placed on the poker layout. With the heat, the ink converts from a solid to a gas without going through the liquid form. The gas then permeates the polyester layout. The polymers in the polyester layout force the inks to bond with combination of heat and pressure. Once the heat is removed, the ink returns to a solid form and the process is complete. The colors are then embedded into the layout rather than printed on the surface. This creates a long lasting digital synthetic casino layout.

Why choose Custom Table Felt for your custom felt projects?

1. We have been making poker table felt since 2003.

2. We have made thousands of poker layouts for home and commercial customers.

3. Our poker layouts last twice as long as other felts under normal use.

4. We are a family operated business that can be reached by phone everyday to assist you.

5. We are accredited members of the BBB of Middle TN with an A+ rating.